November 2019 Newsletter

The design process is almost complete and the team has begun fabrication across all subsystems!

CONCRETE

Our team successfully completed our first round of test pours in which we tested multiple mix designs. Over the next few weeks we will be further iterating on our concrete mix designs and will conduct our next and final round of testing during the first week of December. This will lead into our final ski pours in early to mid December. The team has also taken the initiative to CNC our moulds with our school’s CNC machine, which has been a great experience for all those involved.

TECH-EX

Our team has completed the process of selecting all the games and activities for technical exhibition day, and we’ve begun procuring and testing materials. Our mural design is underway, and last weekend we had a successful first build where a dozen people came out to start building and priming items for the display. Look out for another build coming up in the next few weeks!

THEME

In November, a target that was met for theme included finalizing our branding strategy. We have confirmed our team official logo, our trading patches, as well as our costume logo. Our theme will be mimicking the branding styles of Canada Post, however with a “UofT Mailboggs” twist. This will be the best way to keep a consistent theme. Also, we have finalized suppliers for our mail carrier costume, which will be pursued more in the next month.

SHELL

The shell team spent time finalizing their fabrication process and procuring materials for the mould. In preparation for the safety report, the team also performed simulations for front, rear, side, and rollover impact to ensure rider safety. Based on the results, our toboggan is ready to hit the slopes! This also means our design phase is complete and are planning on laying in our first layer of carbon fibre in the next few weeks.

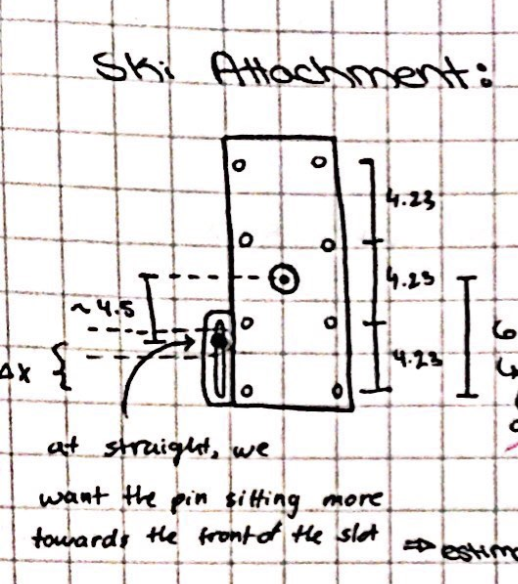

MECHANICAL